ElectroFin®

One of the aspects that should be always taken into consideration in HVAC industry is prevention of damages and deterioration of components, even in the worst conditions. In particular, corrosion often affects heat exchangers and can lead to performance loss and failure. It is therefore very important to provide adequate protection in order to avoid or delay corrosion and its effects. Althermo can provide different coating solutions, according to the type and the site of installation. In fact, not every application is under high risk of corrosion and in those cases there is no need for special coatings. Instead, some environmental conditions or some types of application present high risk of corrosion that should be prevented or reduced. In such scenario consideration of environment and of application is essential to provide the more resistant solution.

CONDITIONS THAT REQUIRE SPECIAL COATING

Environments that put equipment under high risk of corrosion are: coastal and seaside areas, rural areas, polluted urban centres, industrial zones, desert zones. From an installation point of view, types of application with high risk of corrosion are: power stations, chemical, fuel and gas industry, waste disposal and sewage treatment industry.

WHAT IS ELECTROFIN®

For all applications and environmental conditions where standard coatings are inadequate, we at Althermo can offer a special coating treatment that provides the highest and best protection from corrosion.

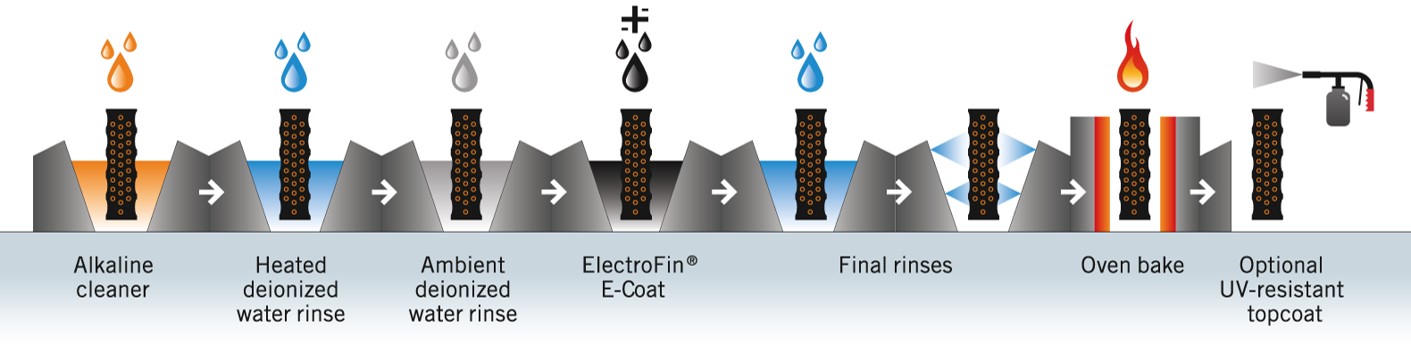

This special coating is ELECTROFIN, a factory-applied electro-deposition coating process that guarantees complete heat exchanger coverage. The coil is immersed in a bath. Here the coil acts as a magnet and attracts the coating to every surface. The result is a thin, flexible, durable, corrosion-resistant coating.

Main feature of this special coating is that, whereas other coating processes fail in covering the entire surface, especially in particular structures such as microchannel or round tube plate coils, ELECTROFIN coating penetrates deep into the 100% of coil surfaces, covering all edges and filling all cracks.

In addition to this, the final stage of the ELECTROFIN coating process provides an extra UV-Resistant Topcoat: a layer is applied by spray to protect the ELECTROFIN coat from UV and ensure durability and long life to coils and microchannel.

BENEFITS OF ELECTROFIN

|

|

Technical Performance Specifications

| ASTM B117-97 | (Salt Spray) | ISO 9227 | Certified @ 6.048 hrs |

| ASTM G85 | (Swaat test – Modified Salt Spray) | ISO 9227 | Tested 4.000 hrs with no failures |

| ASTM D3359-97 | (Cross Hatch Adhesion) | ISO 2409 | 5B Rating/0 European |

| AHRI 410 | (Heat Transfer Reduction) | below 1% | |

| ASTM D7091 | (Dry Film Thickness) | ISO 19840 | 0.6-1.2 mils / 15-30 µm |

| ASTM D870-02 | (Water Immersion) | ISO 2812-2 | above 1,000 hrs |

| ASTM D2794-93 | (Impact Resistance) | ISO 6272-1 | 160 in/lbs direct |

| GM 9540P-97 | (Accelerated Corrosion Test) | 120 cycles | |

| MIL-STD-810F | Method 509.4 (Sand and Dust) | ||

| TEMPERATURE LIMITS | -71 °F to 325 °F / -57 °C to 163 °C (dry load) | ||

| pH RANGE | 3 – 12 | ||

| C5 Mar.& C5 Ind.– High Durability (>15years) | ISO 12944 | (for E-coat+UV) |

Chemical resistance guide (at ambient temperature)

| ASTM B117-97 | (Salt Spray) | ISO 9227 | Certified @ 6.048 hrs |

| ASTM G85 | (Swaat test – Modified Salt Spray) | ISO 9227 | Tested 4.000 hrs with no failures |

| ASTM D3359-97 | (Cross Hatch Adhesion) | ISO 2409 | 5B Rating/0 European |

| AHRI 410 | (Heat Transfer Reduction) | below 1% | |

| ASTM D7091 | (Dry Film Thickness) | ISO 19840 | 0.6-1.2 mils / 15-30 µm |

| ASTM D870-02 | (Water Immersion) | ISO 2812-2 | above 1,000 hrs |

| ASTM D2794-93 | (Impact Resistance) | ISO 6272-1 | 160 in/lbs direct |

| GM 9540P-97 | (Accelerated Corrosion Test) | 120 cycles | |

| MIL-STD-810F | Method 509.4 (Sand and Dust) | ||

| TEMPERATURE LIMITS | -71 °F to 325 °F / -57 °C to 163 °C (dry load) | ||

| pH RANGE | 3 – 12 | ||

| C5 Mar.& C5 Ind.– High Durability (>15years) | ISO 12944 | (for E-coat+UV) |

(*)ElectroFin is NOT suitable for high concentrations of: Nitric Acid, Sodium Hypochlorite, Formic Acid, Hydrofluoric Acid, Sulfuric Acid, Sodium Hydroxide and others.

General description – subject to change or deviations

Kindly consider that the “mix effect” is not considered

Specific environment

| ASTM B117-97 | (Salt Spray) | ISO 9227 | Certified @ 6.048 hrs |

| ASTM G85 | (Swaat test – Modified Salt Spray) | ISO 9227 | Tested 4.000 hrs with no failures |

| ASTM D3359-97 | (Cross Hatch Adhesion) | ISO 2409 | 5B Rating/0 European |

| AHRI 410 | (Heat Transfer Reduction) | below 1% | |

| ASTM D7091 | (Dry Film Thickness) | ISO 19840 | 0.6-1.2 mils / 15-30 µm |

| ASTM D870-02 | (Water Immersion) | ISO 2812-2 | above 1,000 hrs |

| ASTM D2794-93 | (Impact Resistance) | ISO 6272-1 | 160 in/lbs direct |

| GM 9540P-97 | (Accelerated Corrosion Test) | 120 cycles | |

| MIL-STD-810F | Method 509.4 (Sand and Dust) | ||

| TEMPERATURE LIMITS | -71 °F to 325 °F / -57 °C to 163 °C (dry load) | ||

| pH RANGE | 3 – 12 | ||

| C5 Mar.& C5 Ind.– High Durability (>15years) | ISO 12944 | (for E-coat+UV) |